Efficiency Calculation and Analysis of Industrial and Commercial Energy Storage Systems

The industrial and commercial energy storage system brings significant economic benefits to enterprises through various business models such as peak valley arbitrage, demand management, and self use. The efficiency of energy storage systems directly affects their economy and market competitiveness. Therefore, accurate calculation and in-depth analysis of the efficiency of industrial and commercial energy storage systems are of great significance for optimizing system design and improving energy utilization efficiency.

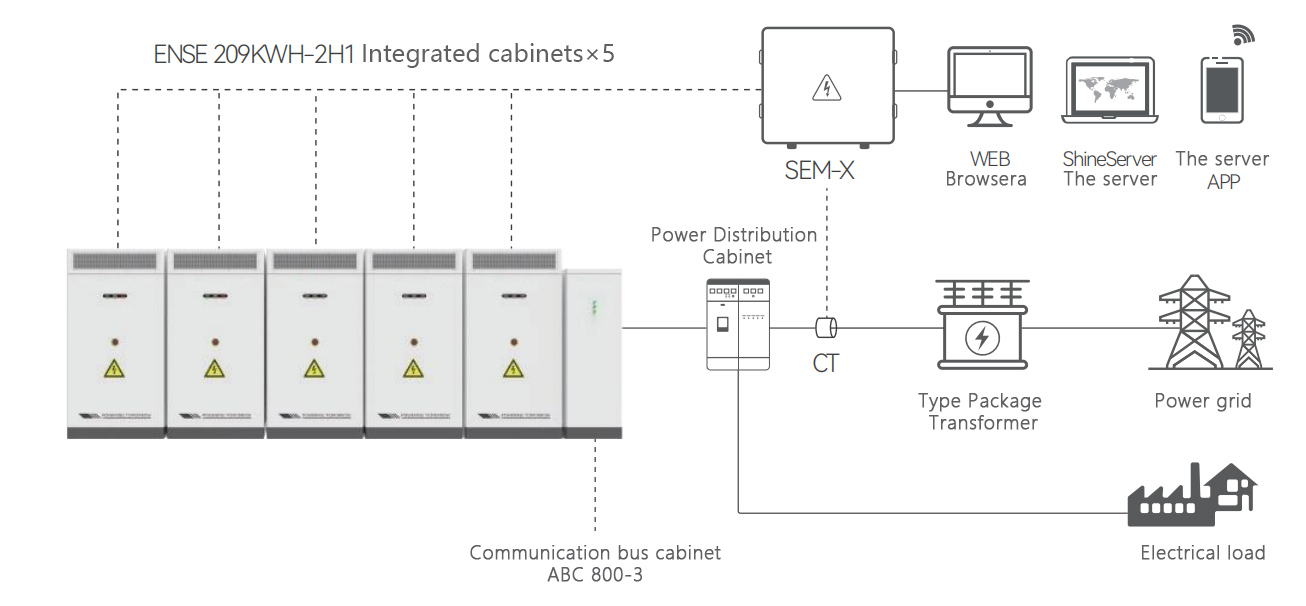

Composition of industrial and commercial energy storage systems

The industrial and commercial energy storage system usually consists of the following parts:

DC side:

Mainly includes the battery system and its management system (BMS). The battery system is the core of the energy storage system, responsible for the storage and release of electrical energy. BMS is responsible for monitoring battery status, protecting battery safety, optimizing battery performance, etc.

AC side:

Including AC/DC inverter system (PCS) and transformer (if connected to high voltage grid). PCS is responsible for converting direct current into alternating current or vice versa to achieve bidirectional flow of electrical energy. Transformers are used to match the voltage of the power grid with that of the energy storage system.

Dispatch Management System:

The Energy Management System (EMS) is responsible for monitoring the operational status of the energy storage system, optimizing charging and discharging strategies, and achieving interaction with the power grid.

Auxiliary systems:

Including air conditioning, fire protection systems, monitoring and alarm systems, etc., used to ensure the safe and stable operation of energy storage systems.

Schematic diagram of industrial and commercial energy storage system

Factors affecting the efficiency of industrial and commercial energy storage systems

The efficiency of industrial and commercial energy storage systems is influenced by various factors, mainly including the following aspects:

Battery efficiency:

The charging and discharging efficiency of the battery itself is a key factor affecting the efficiency of the energy storage system. Different types of batteries (such as lithium-ion batteries, lead-acid batteries, etc.) have different charging and discharging efficiencies. In addition, factors such as battery aging, temperature, and charge discharge rate can also affect battery efficiency.

Power conversion efficiency:

PCS will incur certain losses during the process of energy conversion, and its efficiency directly affects the overall efficiency of the energy storage system; With the development of technology, the efficiency of PCS continues to improve, but there is still room for improvement.

Electrical connection and line losses:

Resistance losses occur when current passes through cables and switchgear, which, although relatively small, cannot be ignored in large-scale energy storage systems.

Auxiliary equipment energy consumption:

Auxiliary equipment such as air conditioning, cooling systems, and lighting will consume electrical energy during operation, thereby reducing the overall efficiency of the energy storage system. Especially in high-temperature environments, the energy consumption of air conditioning systems will significantly increase.

System design and control strategy:

Reasonable system design and optimized control strategy can minimize energy loss and improve the efficiency of energy storage systems. For example, by accurately predicting electricity prices and load changes, optimizing charging and discharging strategies; By implementing reasonable heat dissipation design, battery temperature can be reduced and battery efficiency can be improved.

Definition of energy storage system efficiency

Overall efficiency

According to GBT 36549-2018 "Operation Indicators and Evaluation of Electrochemical Energy Storage Power Stations", the comprehensive efficiency of an energy storage power station is defined as the ratio of the amount of electricity transmitted to the grid and the amount of electricity received from the grid during the production and operation process of the energy storage power station during the evaluation period. That is, comprehensive efficiency=the total amount of electricity transmitted by the energy storage power station to the grid during the evaluation period ÷ the total amount of electricity received by the energy storage power station from the grid.

Charging efficiency

Initial charging capacity on the AC side=(rated capacity of the system x depth of charge and discharge) ÷ charging efficiency of the battery system ÷ rectification efficiency of the energy storage converter ÷ power line efficiency ÷ transformer efficiency+power consumption of auxiliary equipment. Charging efficiency=(system rated capacity x charging and discharging depth) ÷ initial charging amount on the AC side.

Discharge efficiency

Initial discharge capacity on the communication side=(rated capacity of the system x depth of charge and discharge) x charging efficiency of the battery system x inverter efficiency of the energy storage converter x power line efficiency x transformer efficiency - power consumption of auxiliary equipment. Discharge efficiency=initial discharge capacity on the AC side ÷ (rated system capacity x depth of charge and discharge).

Efficiency calculation and analysis:

Battery efficiency is one of the most critical factors in energy storage systems. According to the performance requirements of battery clusters in GB/T 36276-2018 Lithium ion Batteries for Electric Energy Storage, the initial energy efficiency of battery clusters should not be less than 92% under (25 ± 5) ℃ and rated power conditions. However, according to the latest performance requirements of battery clusters in GB/T 36276-2023 Lithium ion Batteries for Electric Energy Storage, the initial energy efficiency of battery clusters should not be less than 95% under (25 ± 5) ℃ and rated power conditions; Considering the above efficiency requirements as initial efficiency, taking into account the actual operation of the energy storage system and the development of market products, the battery system efficiency is temporarily set at 93% (bidirectional).

Efficiency of power conversion system:

The efficiency of power conversion systems includes rectification efficiency and inverter efficiency. According to the market PCS production situation, it is generally taken as 98.5% (one-way).

Power line efficiency:

Power lines generate heat loss when transmitting current. Due to the high integration level of industrial and commercial energy storage integrated cabinets, the DC side line loss can be ignored. The loss of PCS AC side transformer AC side varies depending on the actual situation on site, and is calculated based on the actual loss; For the time being, the one-way efficiency is estimated to be around 99%. Considering bidirectional losses, the power line efficiency is estimated to be around 98.01%.

Transformer efficiency:

At present, the main application of industrial and commercial energy storage integrated cabinets is low-voltage access solutions. The PCS outgoing line of the integrated cabinet is connected to the low-voltage busbar of the existing transformer in the factory area, and the loss efficiency of independent high-voltage transformers is not currently considered.

Auxiliary system power consumption:

Energy storage power stations require certain auxiliary equipment during operation, such as security systems, fire alarm systems, air conditioning systems, etc. The power consumption of these devices accounts for a significant proportion of the total energy consumption of energy storage power plants. Especially in specific environments, due to changes in ambient temperature, the power consumption of the air conditioning system will also increase accordingly.

Example analysis

Taking a certain industrial and commercial energy storage project as an example, its configuration scale is 1MW/2MWh, and the discharge depth is designed at 90%. The main power consuming equipment includes security systems, air conditioning systems, etc. The energy storage system utilizes the electricity price difference to achieve peak valley arbitrage, with a two charge and two discharge cycle, charging and discharging at 0.5C, and completing charging and discharging at full power in two hours; The average operating power consumption of a single system auxiliary power is about 1.5 kW/h.

Charging efficiency of energy storage system:

Initial charging amount on the AC side

=(rated capacity of the system x depth of charge and discharge) ÷ Charging efficiency of the battery system ÷ Rectification efficiency of the energy storage converter ÷ AC line efficiency+power consumption of auxiliary equipment (power consumption of the auxiliary system within 2 hours of charging)

=2000 × 0.9 ÷ 96.44% ÷ 98.5% ÷ 99%+(1.5 × 10) × 2=1944.01kWh.

The charging efficiency of the AC side of the energy storage system is 92.59% (2000 × 0.9) ÷ 1944.01.

Discharge efficiency of energy storage system (considering single discharge):

Initial discharge amount on the AC side=(rated capacity of the system x depth of charge and discharge) x charging efficiency of the battery system x rectification efficiency of the energy storage converter x AC line efficiency - power consumption of auxiliary equipment (power consumption of the auxiliary system within 2 hours of charging)

=2000 × 0.9 × 96.44% × 98.5% × 99% - (1.5 × 10) × 2=1662.78kWh.

The charging efficiency of the AC side of the energy storage system is 1662.78 ÷ (2000 × 0.9)=92.38%.

Comprehensive efficiency calculation:

Under the evaluation cycle of 1 day, with 2 cycles per day (charging for 4 hours, discharging for 4 hours, without considering standby); The daily comprehensive efficiency calculation of energy storage power stations is as follows:

Daily comprehensive efficiency=daily discharge capacity \ daily charge capacity

={2×(2000×0.9×96.44%×98.5%×99%-(1.5×10)×2)}÷

{2 × (2000 * 0.9 ÷ 96.44% ÷ 98.5% ÷ 99%+(1.5 × 10) × 2)}=85.53%.

In practical applications, there may be some deviations in the evaluation period data under different application scenarios and working modes. In project calculations, it is necessary to consider different working environment states and energy storage device situations for reasonable analysis.

Efficiency improvement strategy for energy storage system

Optimize system design:

By optimizing the charging and discharging strategy of the battery system, reduce the self discharge loss of the battery; Optimizing system design, selecting efficient energy storage devices, and implementing control strategies can improve the overall efficiency of energy storage systems.

Introducing intelligent technology:

By introducing intelligent technology, real-time monitoring and scheduling management of energy storage devices can be carried out, and the operating time and power output of energy storage devices can be precisely controlled to improve energy utilization efficiency. At the same time, achieving intelligent integration between energy storage systems and power systems can improve efficiency and stability.

Regular maintenance and inspection:

Due to factors such as system aging, changes in environmental conditions (such as temperature), equipment failures, etc., in order to improve the efficiency of the energy storage system, regular system maintenance and inspection are necessary to ensure the normal operation of the equipment.

summary

In summary, the efficiency calculation of industrial and commercial energy storage systems is a complex but important process that involves multiple factors and links. By understanding system efficiency calculation and optimization design, the efficiency of energy storage systems can be improved and operating costs can be reduced.