How to avoid a decrease in the success rate factor of commercial optical storage systems?

In recent years, with the decrease in domestic battery cell costs and the gradual improvement of time of use electricity pricing mechanisms in various provinces, the photovoltaic and energy storage systems have been advancing rapidly, and the capacity integrated into the power grid has shown significant growth, gradually revealing their impact on the power grid. Among them, the problem of power factor reduction is particularly prominent.

Power factor is an important indicator for measuring the economic operation of a company's electricity consumption. With the widespread use of photovoltaic power generation, some companies may also consider installing energy storage systems. So, how can we avoid a decrease in power factor? The power factor directly affects the energy loss in the power grid, voltage fluctuations and losses in the power supply lines, as well as the safe and economical operation of the power system and the rational utilization of energy.

What is power factor?

In industrial enterprises, commonly used electric motor equipment belongs to inductive loads, which not only consume active power but also absorb reactive power from the power grid during operation. The power factor cos φ is the proportion of active power in the total power (apparent power), that is, cos φ=P/S (P is active power, S is apparent power, power factor is also referred to as PF), and the relationship between reactive power Q and the first two is S ²=P ²+Q ². Therefore, the closer the power factor is to 1, the less reactive power it consumes; On the contrary, the lower the power factor, the higher the reactive power consumption.

Why does the power factor of the factory decrease after installing an optical storage system?

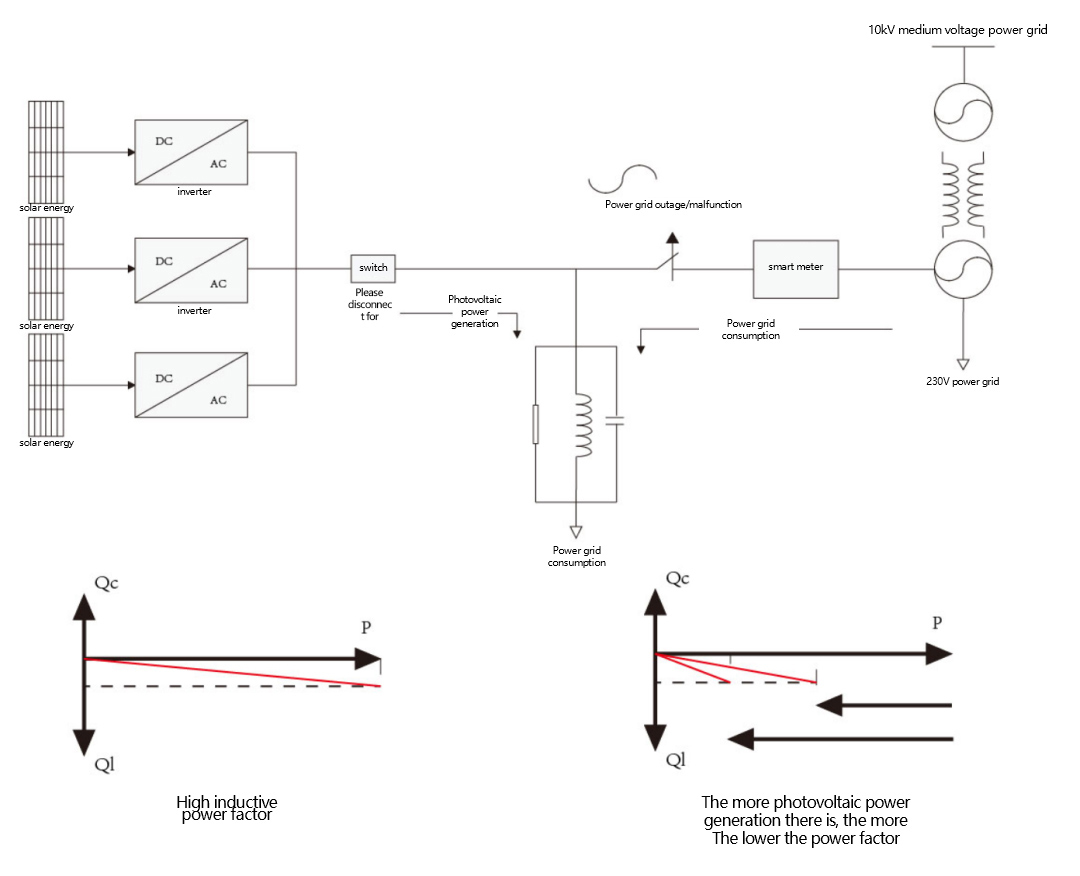

After the distributed photovoltaic system is connected to the plant area, the reactive power output by the grid connected inverter is small. If the capacitive load and inductive load in the plant area account for a large proportion, due to the fact that the photovoltaic power generation and energy storage system only provide active power during the discharge period, while the plant area load consumes both active and reactive power, the active power provided by the photovoltaic power generation and energy storage system is preferentially consumed, resulting in a decrease in the active power obtained from the grid, and all reactive power consumption only comes from the grid. According to the cos φ formula introduced above, for the assessment point of the grid, the power factor will inevitably decrease, which may cause phenomena such as voltage fluctuations and harmonic increases in the power supply system.

What is the solution to avoid power factor degradation caused by commercial photovoltaic and energy storage power plants?

1. Reasonably choose the grid connection method

The choice of grid connection method is crucial to avoid a decrease in power factor. When there is no photovoltaic power generation and energy storage system installed in the factory area, the reactive power compensation system in the grid automatically adjusts and compensates based on the active power supply and reactive power in the grid. Therefore, the reactive power problem in the grid can be automatically compensated through the reactive power compensation equipment set up in the grid, so that the reactive power meets the requirements of the grid.

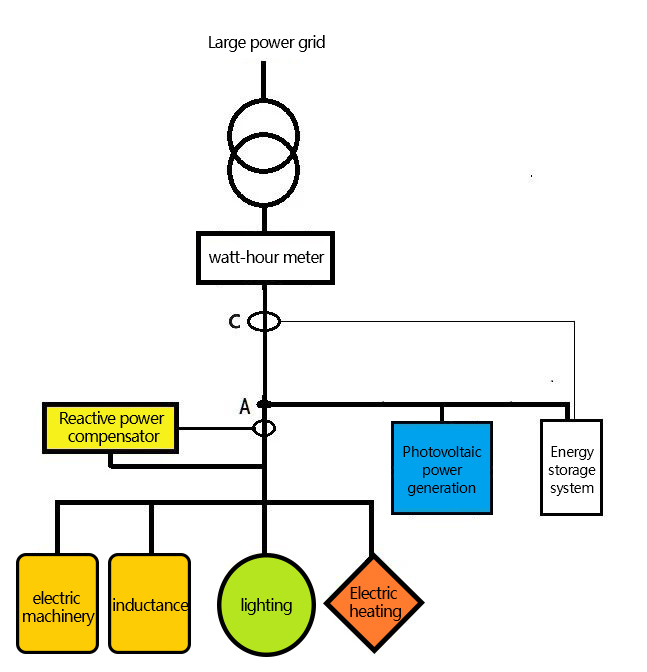

After installing the photovoltaic energy storage system, an effective grid connection method is to connect the photovoltaic and energy storage systems to the grid before sampling the CT in the capacitor cabinet. The connection point of the photovoltaic and energy storage systems is set at point A at the front end of the original reactive power compensation equipment (as shown in the figure below), which means that the photovoltaic energy storage system and the power grid have the same nature and output as the load. This can ensure that the reactive power compensation device can correctly collect the actual power consumption data of the system load, accurately switch the capacitors, and avoid insufficient or overcompensation compensation. Fully utilize the existing reactive power compensation system to reduce investment. In addition, it is necessary to consider that the industrial and commercial energy storage system needs to separately implement anti backflow measures and avoid accidental discharge of surplus electricity during the energy storage discharge period. The anti backflow device CT of the energy storage system needs to be installed at point C in the following figure.

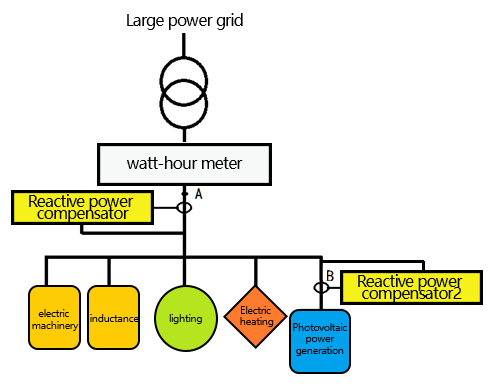

2. Add a dedicated reactive power compensator for the photovoltaic storage system

Install a dedicated reactive power compensation device for this photovoltaic power generation system. Usually, this reactive power compensation equipment should be installed on the output side of the photovoltaic power station to supplement the lack of high-capacity reactive power compensation capability of the photovoltaic power generation system and meet the needs of the power grid. The disadvantage is high cost.

3. Passive power factor regulation through inverters

The power factor PF of the inverter is set to a certain value between 0.8-1, and a portion of the reactive power is compensated by the inverter. Although this method can adjust the power factor, it may result in overcompensation and waste of photovoltaic power generation. Therefore, it is necessary to gradually adjust the settings of the inverter appropriately until the power factor is normal. However, this method has limitations as the inverter will fix a portion of the reactive power output, which may not achieve the highest active power output and affect customer revenue.

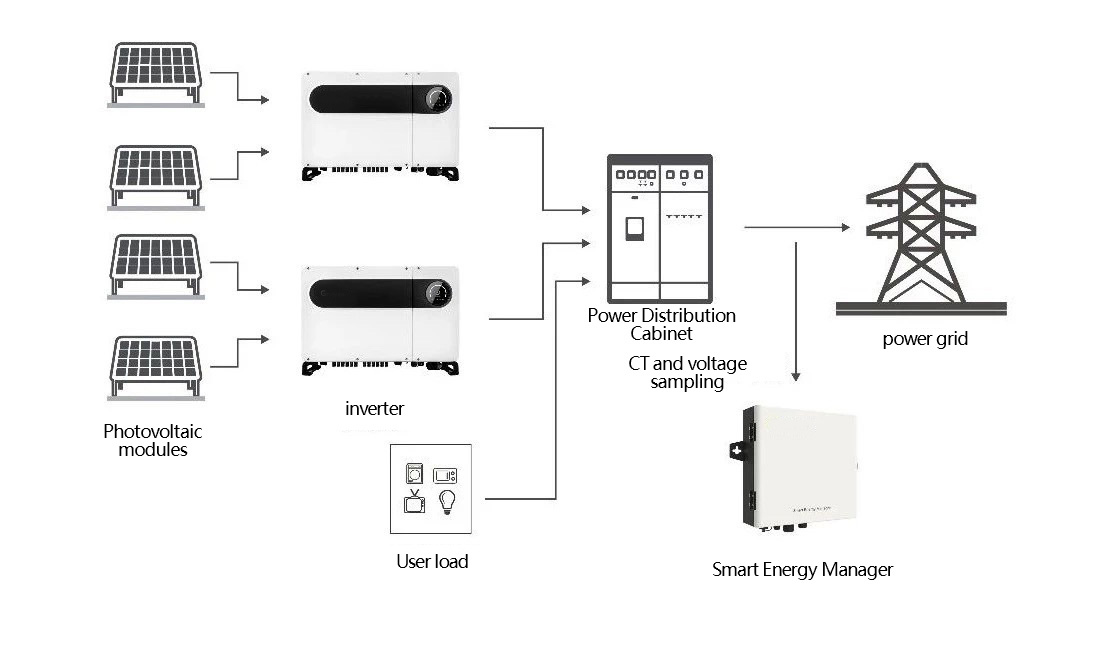

4. Paired with a smart energy manager for dynamic reactive power compensation

The principle is still to use the PF control function of the inverter, install a smart energy manager to collect the power factor values on the bus, continuously calculate the reactive power that the entire system needs to configure, and then send instructions to each inverter through RS485. The advantage of this method is that it does not require an additional capacitor compensation cabinet and has a lower cost.

The power factor issue is one of the important problems

in many photovoltaic power plants, especially in industrial and commercial

photovoltaic storage systems in recent years. It is necessary to fully consider

the existing transformers, reactive power compensation devices, transmission

cables, load types, and power in the design stage. For industrial and

commercial photovoltaic storage systems connected to the grid on the user side,

attention should be paid to the location of the access point to ensure that the

reactive power compensation device can function properly, the power quality

meets the requirements of the grid, and the photovoltaic power station can

operate efficiently and stably, achieving maximum economic benefits while

meeting the power factor requirements of the power company, avoiding fines, and

improving energy utilization efficiency.