Solution for diversified application scenarios of household photovoltaics

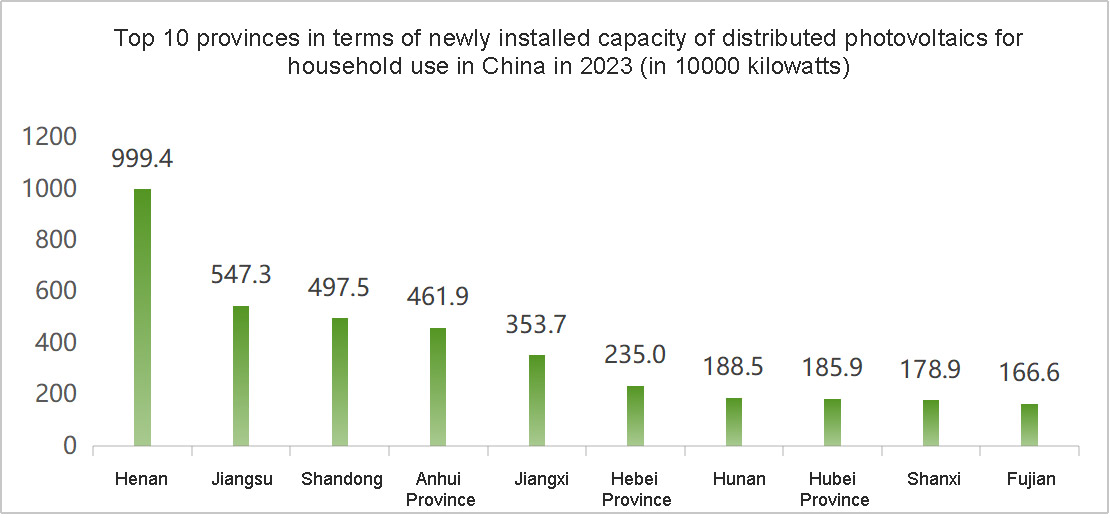

In recent years, as multiple traditional household installed capacity markets have approached saturation, the development of the household market has begun to shift to the south. Provinces such as Jiangxi, Hunan, Hubei, and Fujian have shown outstanding growth in 2023, and various enterprises have included the southern market as an important part of their development. At the same time, southern provinces are actively building new power systems with new energy as the mainstay, and non fossil energy installed capacity and power generation have been increasing year after year, laying a solid foundation for the "dual carbon" goal.

The market shift is also accompanied by changes in the application scenarios of roofs. Compared to the flat roof concrete inclination in the north, the forms of photovoltaic roofs in the south are more diverse, with common ones including herringbone slopes (north-south slopes) and sunrooms.

flat roof

Herringbone slope roof

Sunshine house roof

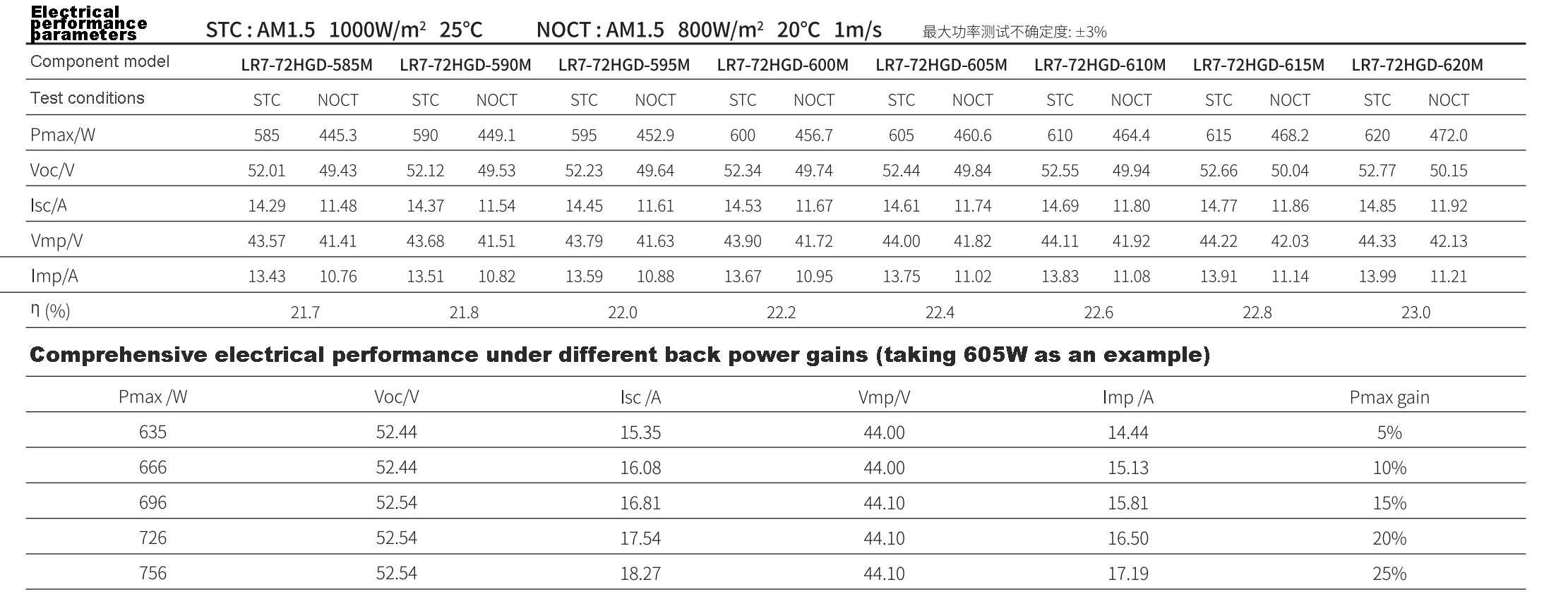

The diversified household photovoltaic application scenarios and the application of 182 and 210 silicon wafer size ultra-high power double-sided double glass modules have raised higher requirements for inverters in the market. Taking the 210 module as an example, considering the back power gain, the theoretical current value of the 210 module can reach up to 18A.

Typical 182mm silicon wafer size component parameters

Typical 210mm silicon wafer size component parameters

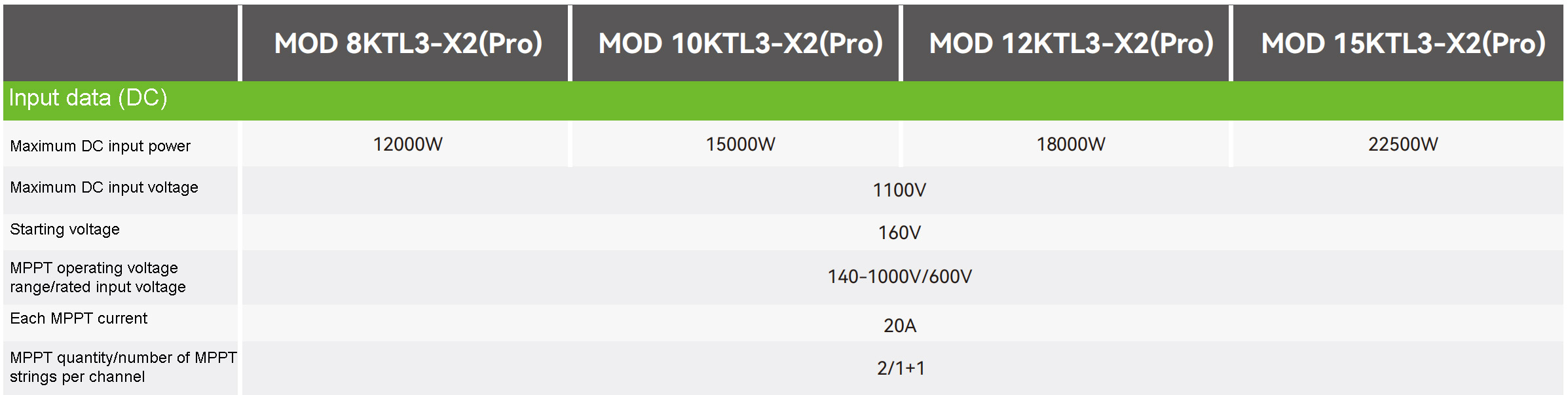

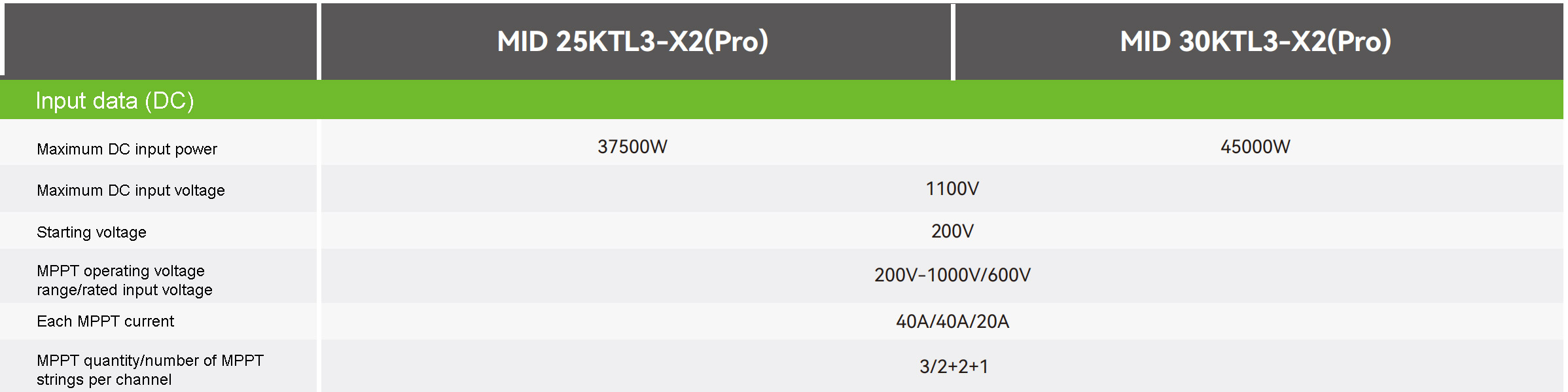

Therefore, inverter manufacturers need to consider achieving full compatibility and providing comprehensive solutions for household scenarios. The inverter is fully compatible with 182&210 high current components, mainly reflected in the number of MPPT channels and string current. Currently, the string current of Pro series inverters has been upgraded to 20A.

MOD 8-15KTL3-X2 (Pro) series

MID 25-30KTL3-X2 (Pro) series

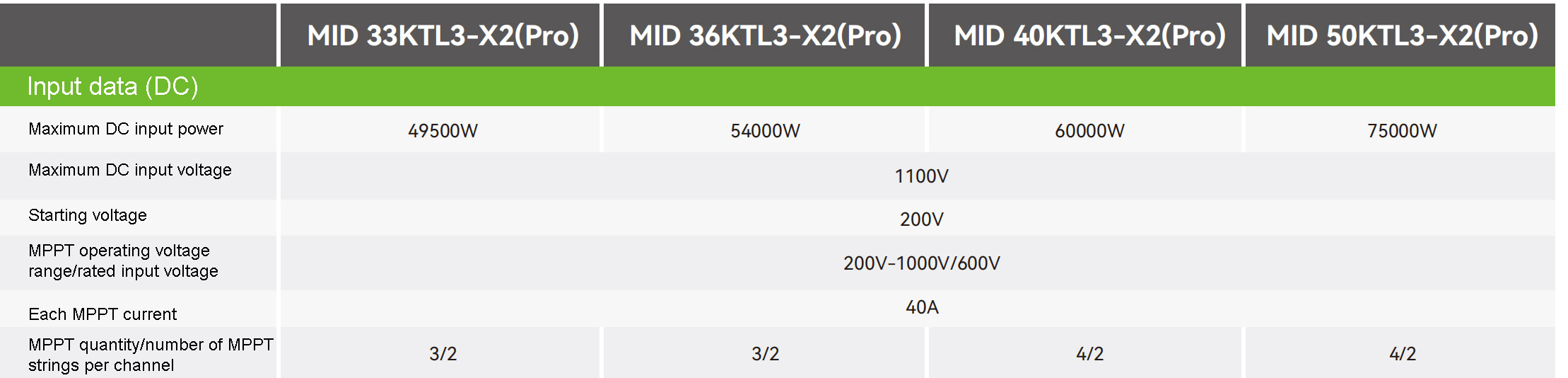

MID 33-50KTL3-X2 (Pro) series

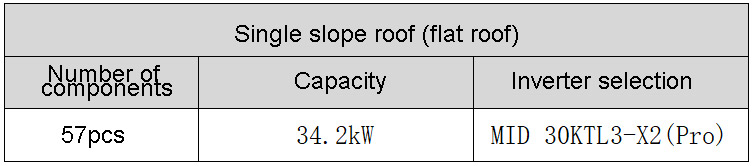

When designing the string of household photovoltaics, it is necessary to consider the impact of factors such as orientation and angle based on the application scenario. The general principle is that the orientation, angle, and number of connected components under one MPPT should be consistent, and the string voltage should be kept within the full load MPPT voltage range as much as possible to ensure that the machine can output full power. Due to the consistent orientation and angle of the single slope roof scene, there is basically no problem with the string design and connection. The following examples illustrate the use of 600W 182 (Voc=52.34V, Impp=13.67A) and 210 (Voc=41.7V, Impp=17.34A) modules, with the inverter power selected being 30kw, which has the highest proportion of household photovoltaics.

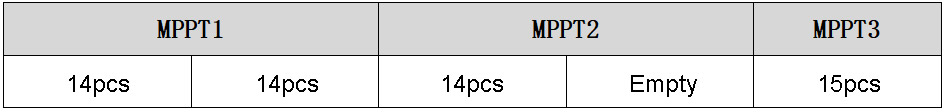

Using 600W/182mm silicon wafer size components, although the 57 components can be divided into 3 groups of 19 pieces in a string, considering the issue of inverter DC overvoltage protection, this design is unreasonable. The connection scheme is as follows:

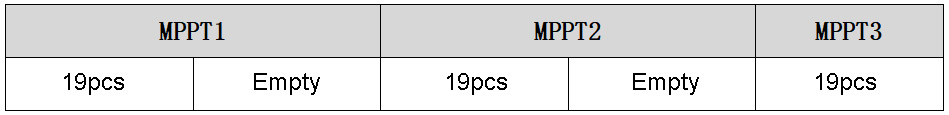

Using 600W/210mm silicon wafer size components, therefore the current of the specification components is relatively high. Priority is given to connecting one MPPT to a group of strings. The connection scheme is as follows:

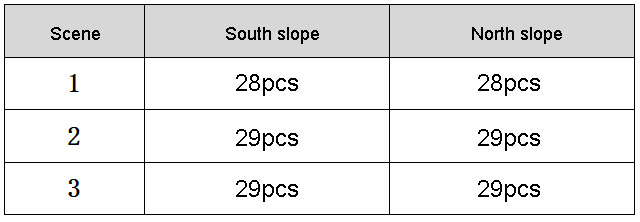

But there may be some special situations in the north and south slope scenes and multi angle sunrooms, taking the 600W (Voc=41.7V, Impp=17.34A) 210 component as an example.

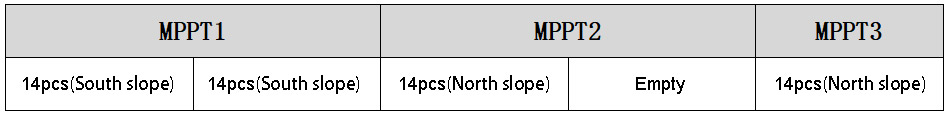

Scenario 1 Solution:

The design of the north-south slope string consists of 14 blocks, with a total of 4 strings. The 2 groups of 14 blocks on the southern slope are connected to MPPT1, while the 2 groups on the northern slope are connected to MPPT2 and MPPT3 respectively. There are many connection schemes here, and there is no need for mixing on the north-south slope.

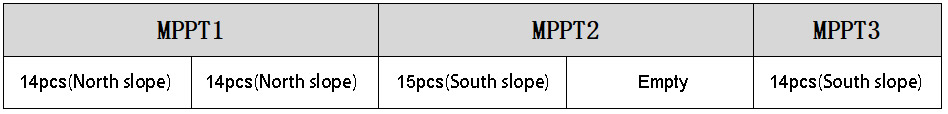

Scenario 2 Solution:

The southern slope is designed with 15 and 14 blocks each in a string, while the northern slope is designed with 2 groups of 14 blocks in a string. The specific connections are as follows.

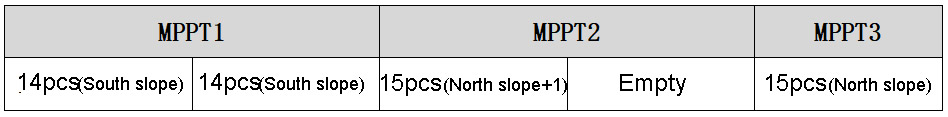

Scenario 3 Solution:

The north and south slopes are designed with 15 and 14 blocks respectively. In this scenario, considering the non mixing factor of the north and south slopes, it is theoretically optimal to use 4 or more MPPT inverters. However, on the market, 4 or more MPPT inverters are all above 40kW, and the cost-effectiveness is not high for use here. If the component inclination angle is not large in the application of sunrooms, mixing can be considered, and priority should be given to ensuring that a large number of strings have a separate MPPT. The specific connection is as follows.

If it is a north south slope roof with a large inclination angle, it is recommended to remove one component from the north slope if the number of components can be adjusted. It is more appropriate to handle it according to the scenario 2 connection plan. If the number of components cannot be increased or decreased, it is possible to consider connecting one component from the south slope to the north slope. The main reason is that the southern slope has better illumination than the northern slope, and the southern slope is mixed with the northern slope, which has a relatively small impact on power generation. The plan is as follows.

Summary:

The above are some common solutions for distributed household photovoltaics. Of course, there are more than that. Welcome to communicate and exchange more. With the rapid growth of the market, photovoltaic companies are investing more effort in developing new technologies, new solutions, and new products will continue to be introduced to the market. Technological updates and more reasonable designs will meet the different needs of more users.