Frequently Asked Questions about Industrial and Commercial Energy Storage Systems (Part 1)

The domestic industrial and commercial energy storage market is developing rapidly. While the market size is advancing rapidly, it is necessary to understand the energy storage system and the design and construction process to ensure the rationality, economy, and safety of energy storage project construction. This article summarizes common issues in the design and construction of industrial and commercial energy storage systems for reference.

Q: What are the application values of industrial and commercial energy storage systems?

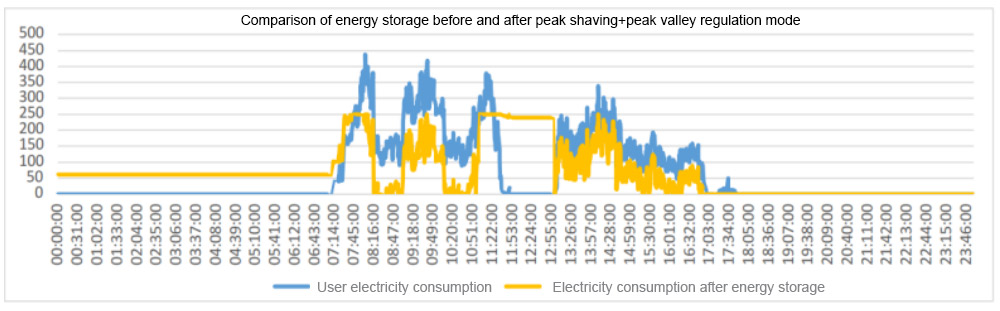

Peak valley arbitrage: Utilizing the difference in peak valley electricity prices, charging during peak and off peak periods, and discharging during peak and off peak periods to reduce the cost of electricity for enterprises.

Balancing demand electricity bills: Energy storage systems can perform peak shaving and valley filling, eliminate peak loads, smooth electricity consumption curves, and reduce demand electricity bills.

Dynamic Capacity Expansion: The user's transformer capacity is fixed, and in general, when the user needs the transformer to be overloaded during a certain period of time, transformer capacity expansion is required. After installing a matching energy storage system, the transformer load can be reduced through energy storage discharge during this period, thereby reducing the cost of transformer capacity expansion and renovation.

Demand side response: After installing the energy storage system, if the power grid issues a demand response, customers do not need to limit electricity or pay high electricity bills during that period. Instead, they may participate in demand response transactions through the energy storage system and receive additional compensation fees.

Q: What are the investment models for industrial and commercial energy storage systems?

There are currently two main operating models for industrial and commercial energy storage: contract energy management and owner self investment. The contract energy management model involves energy investors investing in the procurement and construction of energy storage, signing energy service contracts with electricity consuming enterprises, and sharing energy storage benefits. Generally, energy investors and electricity consuming enterprises share the benefits in a ratio of 90%: 10%, 85%: 15%, etc. The owner self investment model refers to the electricity consumption enterprise investing in the purchase of energy storage, and the electricity consumption enterprise can obtain all the profits through self investment.

Q: What are the requirements for enterprises to install industrial and commercial energy storage power stations?

At present, the main source of revenue for industrial and commercial energy storage is the income brought by the peak valley price difference. Therefore, in areas with large peak valley price differences in industrial and commercial electricity consumption, it is suitable to configure energy storage systems. The specific configuration requirements are as follows.

Enterprises should implement local time of use electricity pricing policies to meet the requirements of energy storage, charging, and discharging, with a large average peak valley price difference. It is generally recommended to pay at least 0.7 yuan/kWh.

If the electricity load period of the enterprise covers the peak period (and peak period, if any), and all electricity is used at night, it is not suitable for construction.

During the valley and flat periods of enterprise electricity consumption, in addition to the original load of the enterprise, the transformer still has sufficient remaining capacity to charge the energy storage system.

Enterprises have fewer downtime for maintenance and off-season days, and the annual available time for energy storage systems is more than 270 days. If the energy storage utilization time is not high, the yield will be low.

Q: What information is needed to know about the electricity consuming enterprise when installing an energy storage power station?

Basic information: type of electricity consumption, basic electricity price, time of use/time of use electricity price, and production status of enterprise electricity shutdown;

Based on the type of electricity consumption, time of use, and electricity price, preliminarily determine the energy storage time of use charging and discharging strategy, determine whether to charge based on capacity or demand, understand the production situation of the enterprise, and determine the annual available time of energy storage.

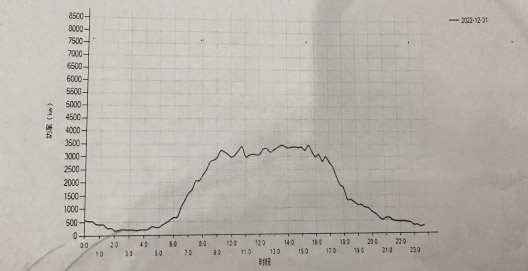

Load electricity data: electricity load data in the past year, average/maximum load power, transformer capacity;

Calculate the energy storage construction capacity based on load data and transformer capacity; Detailed calculation corresponds to the load curve data of each connected transformer, which is used to design the system's charging and discharging time control logic and system economic calculation.

Primary power system diagram, factory floor plan, distribution room layout, cable trench routing diagram, reserved space, etc

Used to determine the installation location of the energy storage system, connect the transformer location, and design the connection plan.

Q: How to calculate energy storage construction capacity based on enterprise electricity load information?

The power of energy storage charging plus the maximum load during the charging period should be less than 80% of the transformer capacity to prevent transformer capacity overload during energy storage system charging.

The load during the peak period of daytime electricity prices should be greater than the peak power of energy storage and discharge.

Providing only monthly/annual electricity consumption cannot reflect the 24-hour electricity load situation of the enterprise, and cannot calculate the energy storage configuration capacity.

Example: A factory in Zhejiang Province implements a 10kV electricity price for industrial and commercial use, with a total transformer capacity of 5000kVA and capacity billing. The enterprise's electricity load is concentrated from 6:00 to 20:00 during the day, covering peak and peak periods, with a maximum load of about 3500kW. The electricity load during valley hours at night is relatively low, with a maximum load of about 500kW.

Configuration plan:

The total capacity of transformers in the factory area is 5000kVA, and the available capacity calculated based on 80% margin is 5000 * 80%=4000kVA

Taking two charging and two discharging as an example, take the power min (X1, X2)

X1=(Transformer capacity * 0.8- Maximum load power during the first night charging interval)=(5000*0.8–500)=3500kW

X2=(Transformer capacity * 0.8- Maximum load power during the second charging interval during the day)=(5000*0.8–3500)=500kWmin(X1,X2)=500kW

During the peak period of daytime electricity prices, the load is greater than 500kW

Energy storage capacity=power * optimal peak shaving time for revenue=500kW * 2H=1000kWh

Q: Can the energy storage capacity be determined based on the total electricity load data and transformer capacity provided by the enterprise?

Generally speaking, if the power consuming enterprise in a low-voltage grid connected energy storage project only has one transformer, the provided electricity load data and transformer load data should be consistent. At this time, the actual installed capacity can be preliminarily determined based on the total load data and transformer capacity; If an electricity enterprise has multiple transformers operating simultaneously, the provided electricity load data is the total load situation of the multiple transformers, which cannot reflect the actual load situation of each transformer. Therefore, it is necessary to understand the load data of each transformer in order to determine the actual installed capacity.

Q: Is it possible to maximize the utilization of photovoltaic energy and improve energy efficiency in photovoltaic energy storage integration projects?

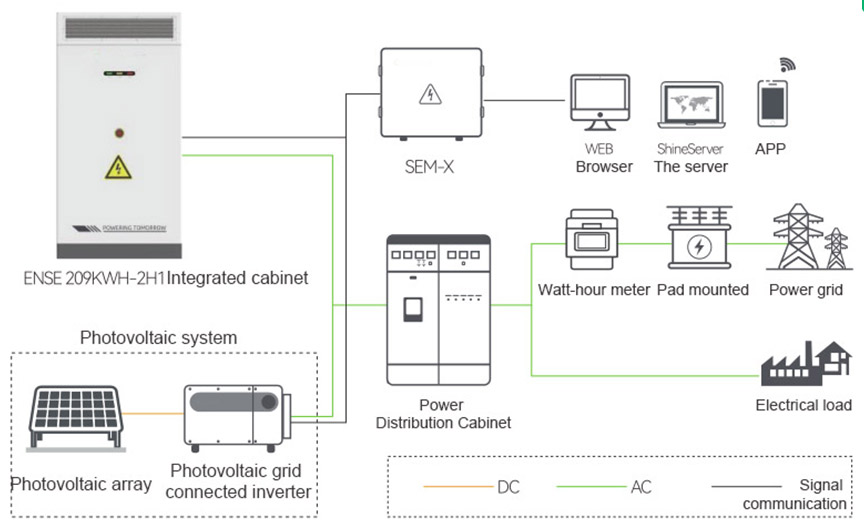

At present, industrial and commercial photovoltaic energy storage projects can be achieved through the exchange coupling of energy storage and photovoltaics. By monitoring and controlling the energy storage integrated cabinet and photovoltaic inverter, and using the energy management system to set the "load priority" mode, Growatt can achieve priority utilization of energy and improve the utilization ratio of photovoltaic energy sources.